In vitro test for evaluation of eye irritation based on opacity and permeability

TG 437

The BCOP (Bovine Corneal Opacity and Permeability) is organotypic assay used to evaluate the potential ocular irritancy of a test article. This assay uses living bovine corneal tissue, obtained as a by-product from abattoirs

Types of injury caused by exposure to the test article are quantitatively measured by changes in opacity and permeability to fluorescein.

The BCOP assay allows for the investigation of the mechanism of the damage caused.

OECD 437: Bovine Corneal Opacity and Permeability Test (BCOP)

Background

The scientific community has been working vigorously towards Reduction/Replacement/Rehabilitation of the animals used for research. The agencies like ICCVAM, ECCVAM with active involvement of scores of scientists have been working on developing the experimental protocols for ensuring minimisation of the in-vivo studies. Amongst these, the most painful one was the studies requiring testing the compounds for their potential to cause severe pain and distress in the animal under testing. Their efforts led to development of a harmonized study protocol, which was one of the test method formalized by OECD TG No. 437 replacing the in vivo testing of corrosive test articles by a new in vitro eye irritation. This test enables prediction of across the full range of irritation for different chemical classes. BCOP test method is on of the vital test in the series of test recommended by OECD as it addresses corneal effects, which are the major driver of classification in-vivo when considering the UN GHS classification.

Introduction

The purpose of this study is to evaluate the eye hazard potential of a test item by measuring its ability to induce opacity and increased permeability in an isolated bovine cornea. Toxic effects to the cornea are measured by: (i) decreased light transmission (opacity) and (ii) increased passage of sodium fluorescein dye (permeability). The opacity and permeability assessments of the cornea following exposure to a test chemical are combined to derive an In Vitro Irritancy Score (IVIS), which is used to classify the irritancy level of the test chemical.

The BCOP test method is an organotypic model that provides short-term maintenance of normal physiological and biochemical function of the bovine cornea in vitro. The method used Corneas of Bovine eyes from the abattoirs. The eyes are of no commercial value and are discarded as biological waste.

Method Discription

The eye are collected from the abattoirs and transported carefully to the labs at JRF. The eyes are visibly inspected and the corneas, free of defects, are dissectedand used as test system. The dissected corneas are then loaded on the specially designed cornea holders (Figure – 1)

Figure 1: The cornea holder:

Cornea Holders (Pictures of the Instrument and holders adopted from the supplier manual)

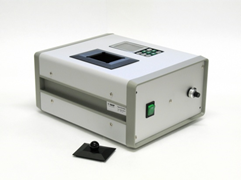

A known amount of test item is applied to the anterior surface of the cornea and then the corneas are incubated for requied time (depending upon the physical form of the test item). At the end of the incubation period Opacity is measured using the Opacitometer (Manufactured by Duratec, Germany)

(Figure 2)

After recording the results for opacity the corneas are subjected to experimental protocol of treating the cornea with sodium fluorescein solution to the anterior surface of the cornea. The post incubation the fluid is collected from the posterior part of the cornea optical density or absorbance values are check at OD490.

Using the Opacity and permeability value in vitro irritancy score (IVIS) is derived for each test item based upon which the test item is classified. If the test item is classifed under “Category 1” using this test method then furter testing will not be required.

Our team of scientists at JRF have successfully developed and established this test at JRF. The standard operating procedures have been established and a GLP validation has been successfully undertaken. The results described in the table below, go on to establish the successful validation at JRF.

Services available at following locations: